路易斯酸驱动不对称界面电子分布以稳定活性物质以实现高效中性水氧化

第一作者:赵晟

通讯作者:彭生杰教授*

通讯单位:南京航空航天大学

论文DOI:10.1002/adma.202308925

中性析氧反应(OER)具有独特的反应环境,反应动力学极其缓慢,这给催化剂的设计带来了重大挑战。在本研究中,作者精心构建了功函数可调的钨酸盐(Ni-FeWO4)与Lewis酸WO3之间的内建电场,调节了界面电子的不对称分布,促进了钨酸盐中Fe位的电子聚集,减缓了Fe在OER电位下的快速溶解,从而保留了具有优化OER反应途径的活性羟基氧化物。同时,Lewis酸WO3增强了电极表面附近羟基的吸附,改善了传质。本研究加深了对OER催化剂在中性环境下重构的认识,为能量转换技术的发展铺平了道路。相关工作以《Lewis Acid Driving Asymmetric Interfacial Electron Distribution to Stabilize Active Species for Efficient Neutral Water Oxidation》为题在《Advanced Materials》上发表。

与在恶劣的碱性和酸性环境下的反应相比,在中性介质中电解水裂解析氢反应的反应条件更温和,从而减少了设备的腐蚀,延长了电解槽的使用寿命。然而,与对碱性OER催化剂广泛而深入的研究相比,非贵金属材料在中性环境下的反应过程还需要更多的阐明。在中性OER过程中,电极附近氢氧根离子的快速消耗可以减少电极附近的传质,从而影响催化剂的反应动力学。中性条件下反应环境的独特性给高效OER催化剂的设计提出了巨大的挑战。

Figure 1. a) Scheme of the preparation process of Ni-FeWO4@WO3/NF-1. b) XRD pattern of Ni-FeWO4@WO3-1. c) TEM and d) AC-TEM images of Ni-FeWO4@WO3/NF-1. XPS fine spectra of e) Ni 2p and f) Fe 2p of Ni-FeWO4/NF-1 and Ni-FeWO4@WO3/NF-1. Normalized g) Ni K-edge, and h) Fe K-edge XANES Ni-FeWO4/NF-1, Ni-FeWO4@WO3/NF-1, and the corresponding references. i-j) The corresponding k3-weighted Fourier transforms.

Figure 2. a) LSV polarization curves of OER and b) Tafel plots of Ni-FeWO4/NF-1, Ni-FeWO4@WO3/NF-1, RuO2/NF and WO3/NF in 1 M PBS. c) Comparison of the overpotentials at 10 mA cm−2 and Tafel slopes of Ni-FeWO4@WO3/NF prepared using different precursor dosages. d) EIS Nyquist curves of Ni-FeWO4/NF-1, Ni-FeWO4@WO3/NF-1, RuO2/NF and WO3/NF. e) Linear fitting of the current density versus scan rates of Ni-FeWO4/NF-1, Ni-FeWO4@WO3/NF-1, RuO2/NF and WO3/NF, and the corresponding value of Cdl. f) Chronopotentiometric test of Ni-FeWO4@WO3/NF-1 at 10 mA cm−2 and the inset displays the LSV polarization curves of Ni-FeWO4@WO3/NF-1 before and after 3000 CV cycles. g) The dissolution rates of the Ni and Fe in Ni-FeWO4/NF-1 and Ni-FeWO4@WO3/NF-1 obtained by inductively coupled plasma-mass spectrometry (ICP-MS) during the chronopotentiometry tests. h) The overpotentials of Ni-FeWO4/NF-1 and Ni-FeWO4@WO3/NF-1 at 10 mA cm−2 in neutral and alkaline environment. i) Comparison of the overpotentials at 10 mA cm−2 and Tafel slopes with the recent materials for neutral OER.

Figure 3. In-situ Raman spectra of a) Ni-FeWO4/CP-1 and b) Ni-FeWO4@WO3/CP-1 under different operated potentials (VS. RHE). c) Normalized peak intensity of the Raman signals corresponding to FeOOH. The content of Fe2+, Fe3+, Ni2+and Ni3+ in c) Ni-FeWO4-1 and d) Ni-FeWO4@WO3-1 before and after OER cycling. f) Zeta potential values of WO3, Ni-FeWO4-1 and Ni-FeWO4@WO3-1. EIS Bode plots of g) Ni-FeWO4/CP-1 and h) Ni-FeWO4@WO3/CP-1 at the potentials of 1.25-1.85 V vs. RHE. i) Schematic illustration of the neutral OER process of Ni-FeWO4@WO3/NF-1.

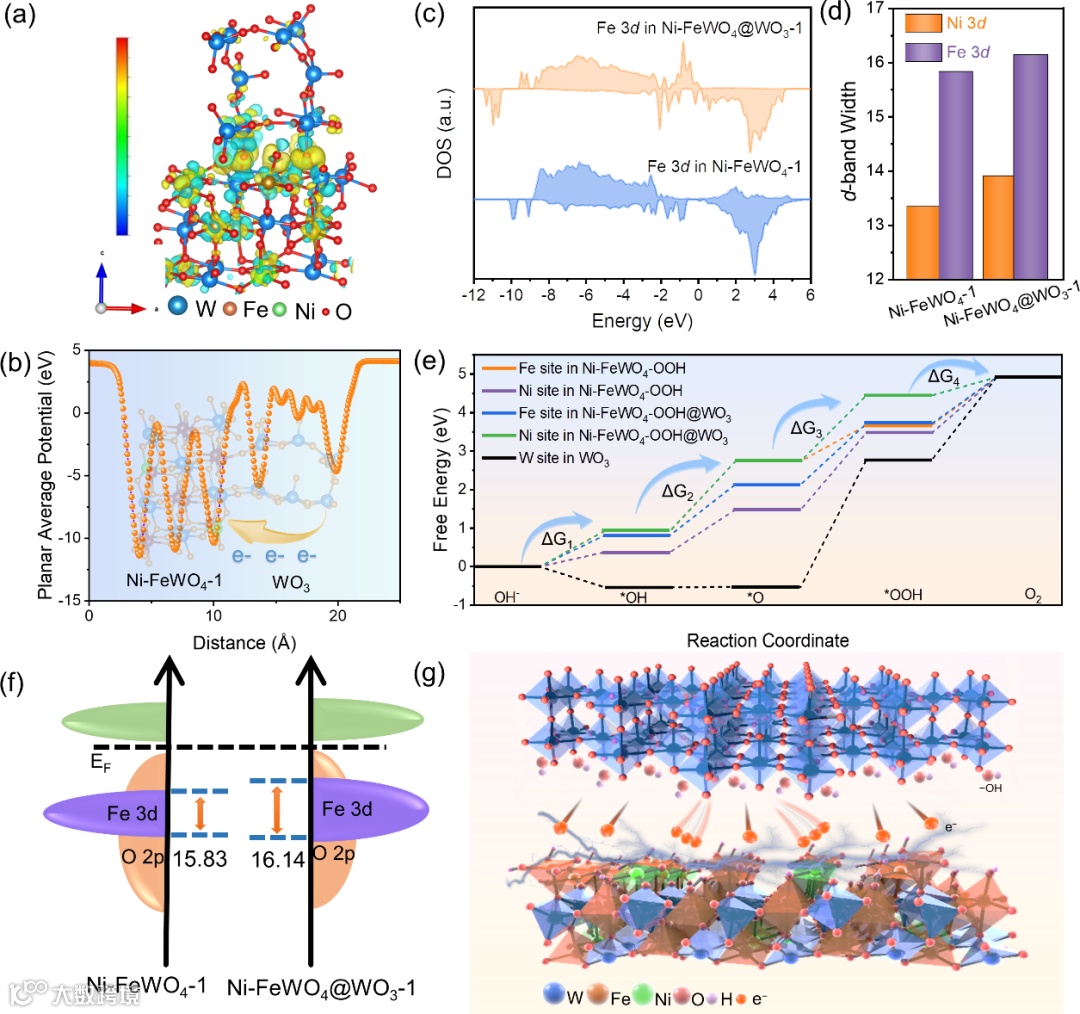

Figure 4. a) Charge density difference of Ni-FeWO4@WO3-1. b) Plane-average electron difference diagram of the interface between Ni-FeWO4 and WO3. c) Projected DOS of Fe 3d in Ni-FeWO4-1 and Ni-FeWO4@WO3-1. d) The d-band widths of Fe 3d and Ni 3d in Ni-FeWO4-1 and Ni-FeWO4@WO3-1. e) Free energy profiles of different OER intermediates at 0 V for Fe site in Ni-FeWO4-OOH, Ni site in Ni-FeWO4-OOH, Fe site in Ni-FeWO4-OOH@WO3, Ni site in Ni-FeWO4-OOH@WO3, and W site in WO3. f) Variation of the d-band widths of Fe 3d in Ni-FeWO4-1 and Ni-FeWO4@WO3-1. g) Schematic illustration of the electron barrier layer for the protection of Fe, and Ni sites in Ni-FeWO4@WO3.

Figure 5. a) Conceptual model of the water splitting in 1 M PBS. b) LSV polarization curves of Ni-FeWO4@WO3/NF-1 ‖ Pt/C/NF, Ni-FeWO4-1 ‖ Pt/C/NF and RuO2/NF ‖ Pt/C/NF for the neutral water splitting. c) The corresponding chronopotentiometry tests of Ni-FeWO4@WO3/NF-1 ‖ Pt/C/NF, Ni-FeWO4-1 ‖ Pt/C/NF at 10 mA cm−2. d) Schematic illustration of neutral seawater electrolyzer assembled with Ni-FeWO4@WO3/NF-1, Ni-FeWO4/NF-1 and RuO2/NF as the anodes and Pt/Ti felt as the cathodes. e) Steady polarization curves of neutral seawater electrolyzer at 60 °C. f) Faraday efficiency tests of neutral seawater electrolyzer using Ni-FeWO4@WO3/NF-1 ‖ Pt/Ti felt at 200 mA cm−2. g) Chronopotentiometry tests of Ni-FeWO4@WO3/NF-1 ‖ Pt/Ti felt and Ni-FeWO4/NF-1 ‖ Pt/Ti felt for neutral seawater electrolyzer. The insets show the water contact angle tests of Ni foam and Ni-FeWO4@WO3/NF-1. h) Comparison of the performance parameter of Ni-FeWO4/NF-1, and Ni-FeWO4@WO3/NF-1 in neutral OER and the corresponding MEA for neutral seawater electrolyzer.

综上所述,本研究成功构建了内置可调电场的Ni-FeWO4@WO3/NF自支撑电极,实现了在中性介质中高效稳定的OER。在内建电场中,Lewis酸WO3不仅作为电子供体为钨酸盐中的Fe位提供了电子,而且促进了-OH在电极表面的吸附,加速了传质。此外,Ni-FeWO4的功函数调节改变了WO3的缺电子状态,实现了合适的内置电场界面电子不对称分布。这些因素抑制了快速铁浸出,从而稳定了中性OER过程中产生的活性氢氧化物。

彭生杰,南京航空航天大学教授,博士生导师,英国皇家化学会会士(FRSC)。入选国家青年人才,江苏省特聘教授、江苏省“双创人才计划”、江苏省“六大人才高峰”高层次人才、南航首批“长空学者”,主持江苏省杰出青年基金、国家自然基金面上项目、江苏省双碳专项和南京留学人员科技创新项目。2010年于南开大学取得博士学位,导师陈军院士。随后分别加入南洋理工大学Prof. Yan Qingyu和新加坡国立大学Prof. Seeram Ramakrishna(英国工程院院士)课题组进行博士后研究。近十年来,一直从事微纳米结构及新型功能材料的设计、合成及其电化学储能与催化研究,取得了一系列创新性科研成果。其中以第一/通讯作者在Nat. Commun., J. Am. Chem. Soc., Angew. Chem. Int. Ed.和Adv. Mater. 等发表SCI论文130余篇,共计发表论文180余篇,研究成果受到国际国内同行的广泛关注,被引用1.3万余次,H-index 60。目前担任《eScience》,《Advanced Fiber Materials》等六个中英文期刊青年编委,出版学术专著三部,撰写英文专著一章。申请中国发明/授权专利30项。

课题组主页:https://www.x-mol.com/groups/peng_shengjie

声明

“邃瞳科学云”直播服务

扫描二维码下载

邃瞳科学云APP