Introduction

Blindly trusting "Gold Supplier" badges without checking the fine print

Obsessing over factory size while ignoring the boss's business philosophy

Chasing rock-bottom prices and sacrificing quality control

Skipping background checks until you discover their legal troubles the hard way

01

The Current State of Foreign Trade Factories in 2025

Factory Distribution Patterns

Platform Reality Check: 1688 vs. Alibaba International

Price Verification 101

Check historical transaction records: Ask for real order screenshots from the past 3 months (client info can be blurred)

Test MOQ flexibility: Real factories usually accept 100-500 trial units; traders often force 1000+ minimums

Demand production videos: Random requests for workshop assembly line or raw material warehouse footage—factories that can deliver instantly are legit

How Factories Think About Cooperation

02

Core Factory Screening Methods

Initial Online Vetting

The 5-Dimension Checklist

| Screening Dimension | Key Verification Metrics | Red Flags | Verification Tools |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In-Depth Background Checks

Dual-Channel Verification Model

On-Site Factory Audit Essentials

3 Pre-Audit Must-Dos

Clarify your core order requirements: capacity limits, quality standards, delivery timelines

Prepare killer questions: "How do you handle labor shortages during peak seasons?" "What's your equipment maintenance schedule?"

Insist on meeting the decision-maker: You need the factory boss or production manager—avoid getting stuck with sales reps who filter information

The Critical "Three Looks" During Audits

03

Effective Communication & Negotiation Strategies

No-Order Communication Hacks

The Rookie's Resource-Building Playbook

Step 2: Craft a killer virtual inquiry—Pose as a "potential buyer" to gauge factory interest

Step 3: Transition to trading company identity—Highlight your "existing client base" and growth potential

Step 4: Drill down on details—Ask about production capabilities and customization flexibility to assess fit

Virtual Client Inquiry Template

Dear Mr. Li,

We are a trading company specialized in outdoor gear distribution, currently working with major e-commerce platforms in UK (e.g., ASOS, Decathlon). Our buyer is interested in your hydraulic camping tents after seeing your product video on 1688.

FOB price for 2-3 person tent (MOQ 500pcs)

OEKO-TEX certification status

Sample lead time & cost

[Your Name]

[Your Contact]

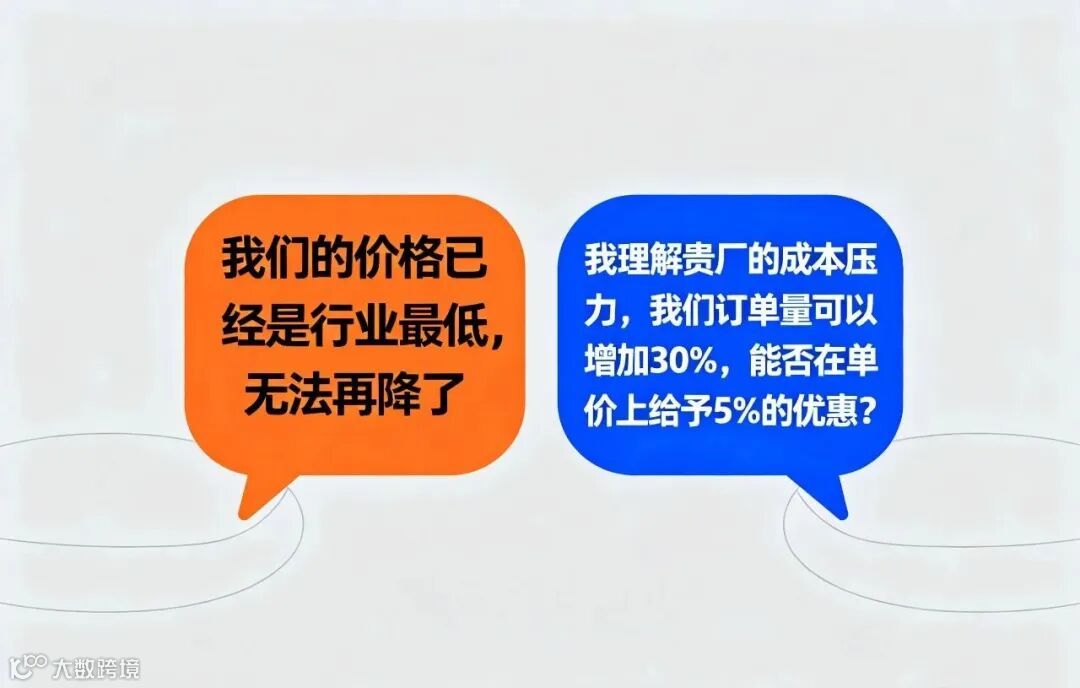

Price Negotiation Tactics That Work

The "Next-Day Order" Success Story

Day 1: Confirm details, casually mention "other factories offered better rates"

Day 2: Send mock client logo designs, say "client approved 5% price increase but needs confirmation today"

The close: Factory fears losing the order and accepts 95% of original price

The Three-Part Response Formula

Empathize: "I totally get why price matters—cost control is crucial for both of us"

Educate: "This product uses premium materials costing 8% more than competitors, but reduces your customer complaints by at least 15%"

Solve: "If you bump first order quantity from 500 to 800 units, I can get the factory to drop another 3%"

04

Long-Term Cooperation & Risk Management

Core Factory Evaluation Criteria

9 Critical Due Diligence Items

Boss interview assessment—Test their industry trend insights

Half-day factory observation—Visit during peak hours (9:00-12:00) to see management in action

Export record verification—Check Customs "Import-Export Credit Information Platform"

Strength verification—Factory size, core equipment, employee roster, monthly output

Supply chain transparency—Top 3 raw material supplier contracts

Industry standing analysis—Patent count, industry association roles

Key team interactions—Talk to production supervisors and QC managers

Trade show verification—Past 2 years' exhibition records

Response speed test—Request product testing reports within 3 days

Cautionary Tale: The Short-Sighted Factory Owner

Red Flags of Unreliable Factories

Risk Matrix & Response Strategies

|

|

|

|

|

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Raw material price hikes | Medium | High | Adopt "cost-sharing": Split 50% of the increase |

Raw Material Price Hike Response Script

"Mr. Wang, I understand the 20% copper price hike is hitting you hard (empathy). But our analysis shows materials only account for 40% of total cost—so a reasonable increase would be 5-6% (data backup). How about we split it 50/50 with a 5% hike, and I'll increase my order from 500 to 800 units (solution)."

2025 Factory Selection Trends

| Metric | Smart Factory (2025) | Traditional Factory |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Smart production capabilities: Minimum order flexibility and rush order response time

Supply chain health: ≥70% local workforce, at least 2 backup material suppliers

Exhibition participation: Prioritize factories exhibiting at top 3 industry shows in past year

SOHO Newbie Survival Guide

Zero-Resource Startup Blueprint

Step 2: Product portfolio development—Gather 5-8 target products with high-res images, spec sheets and English descriptions

Step 3: Client acquisition blitz—Send 20 customized cold emails daily using Google Search and LinkedIn

Step 4: Leverage inquiries for factory leverage—Collect 3-5 preliminary client inquiries as negotiation chips

Budget-Friendly Audit Alternatives

Video Audit "Must-Shoot" List

Production equipment close-ups—Capture model numbers and operating status; prioritize brand-name new machines

QC records—Must show product models, inspection items and signature sections

Packaging workshop overview—Check for consistent materials and standardized procedures

Raw material labels—Shoot ingredient lists and origin information

Worker proficiency—Randomly film operator skills and uniform standards

Low-Cost Background Check Tools

| Tool Name | Core Function | Pro Tips |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

Cross-border Payment / International Platform Onboarding

/ Sourcing in China / Global Customer Outreach

Contact us on WeChat for personalized end-to-end foreign trade solutions